Shenzhen Office Address:

Shenzhen Office Address: Nanchang Office Address:

Nanchang Office Address: Qingdao Office Address:

Qingdao Office Address: Dalian Office Address:

Dalian Office Address: Shanghai Office Address:

Shanghai Office Address: Xiamen Office Address:

Xiamen Office Address:

Household Appliances | |

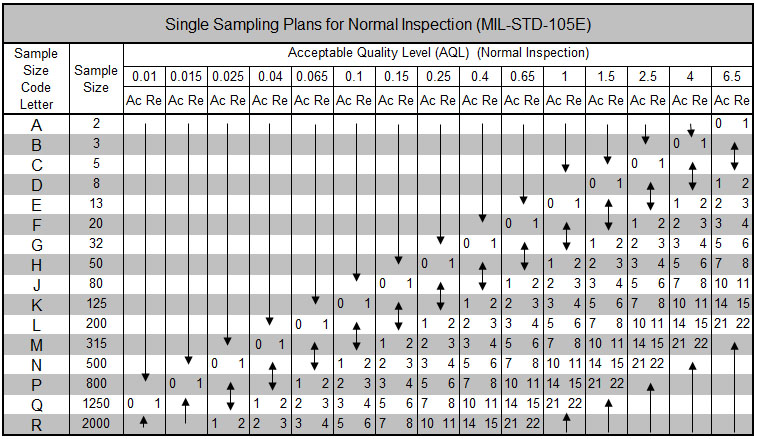

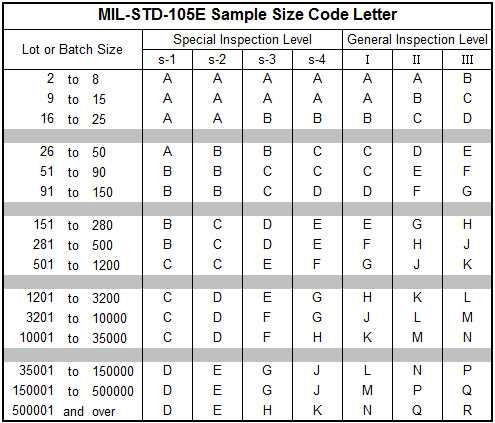

QCIC technical engineers work closely with your team to customize one of our standard household appliances inspection checklists by incorporating the key risks and unique specifications of your product. QCIC inspectors verify the quality of mass production based on your Acceptable Quality Limits (AQL), provide an overview of the finished goods' quality, and identify areas for production that require improvement. We also perform a series of tests and assess compliance with your product's specifications and reference samples. Main tests performed during an inspection of Household Appliances ---Hi-pot test ---Earth continuity test ---Power cord pull test ---Stability test ---Power consumption test ---Motor rotation speed measurement ---Internal construction review ---Working current/voltage check ---Noise level measurement ---Waterproof test ---Product parameter check ---Product function/performance test ---Workmanship review ---Frequency checking ---Working distance for wireless device ---Impedance check ---Signal-to-noise ratio ---Frequency response test for speaker and microphone | |

Consumer Electronics | |

QCIC technical engineers designed a range of global conformity assessments specific to consumer electronics and customize each inspection by combining standard QCIC inspection checklists with your unique product specifications. On-site, QCIC inspectors verify the quality of mass production based on your Acceptable Quality Limits, perform product specific function and safety tests, and assess compliance to your product's specification and approval sample. We conduct thorough checks including the battery, functions, instruction manual, warning messages, accessories, labeling, packaging, packing. Main Tests performed during an inspection of Consumer Electronics ---Hi-Pot test ---Stability test ---Power cord pull test ---Power consumption test ---Product function/performance test ---Noise level measurement ---Frequency compatibility check ---Memory size check ---Remote control distance ---Working current ---Voltage check ---Workmanship review | |

Lighting | |

QCIC technical engineers take into account your quality objectives and unique product specifications, to build a customized lighting inspection checklist. QCIC inspectors verify the mass production workmanship based on your Acceptable Quality Limits (AQL), provide an overview of the finished goods' quality, and highlight the key production areas requiring improvement. We also perform on-site tests and assess compliance with your product's specifications and reference samples. Main Tests performed during an inspection of Lighting ---Hi-pot test ---Stability test ---Earth continuity test ---Power cord pull test ---Waterproof test ---Running test with lighting for 4 hours ---Dimming test ---Power consumption test ---The length of power cord check ---Lighting source test ---Torque test ---Installation test for lamp and lamp holder | |

Furniture | |

QCIC technical engineers, work hand in hand with your team to understand key risks. This ensures the QCIC product-specific Furniture inspection checklist is fully customized to your needs. QCIC inspectors verify the quality of mass production based on your Acceptable Quality Limits (AQL), perform product function and safety tests, and assess compliance with your product's specifications and authorized samples. We also check the suitability of packaging to protect your furniture, marking, instruction manuals, accessories, and barcodes. Main tests performed during an inspection of Furniture ---Performance check ---Size measurement ---Material & color check ---Adhesive test on logo ---Static loading test ---Stability check ---Moisture content ---Rub test on fabric ---Fatigue test ---Wobbly base test ---Smell test ---Assembly check | |

Homeware / Kitchenware | |

Quality control of homeware requires considerable hands-on expertise and a keen focus on detail. QCIC technical engineers customize our standard homeware inspection checklists to include your main concerns and specific requirements for each product. QCIC inspectors then conduct a series of on-site checks to verify the quality of mass production based on your Acceptable Quality Limits (AQL), international regulations, safety standards, and our extensive industry know-how. Main tests performed during an inspection of Homeware / Kitchenware ---Real function check ---Safety check ---Smell test ---Flow test ---Abuse test ---Impact test on lid ---Stability check ---Capacity check ---Flushing test ---Water leaking test ---Wobbly base check ---Temperature accuracy test ---Heat resistance test ---Loading test ---Splash test | |

Garments / Textiles | |

Each inspection is customized by combining our standard QCIC garments inspection checklists with your unique product specifications. We verify the quality of mass production based on your Acceptable Quality Limits (AQL), identifying and classifying defects to offer an overview of your product's quality. We also perform on-site tests and assess compliance to your product's specification and approval sample. Checks include sizing, measurements, labeling, packaging, and packing. Main tests performed during an inspection of Garments and Textiles ---Color shading ---Colorfastness check (Rub test) ---Fabric weight test (for knitted garments) ---Symmetry check ---Size fitting test ---Adhesive check (logos, printings, markings fastness) ---Waterproof test ---Down feather leakage testing ---Fasteners fatigue and zip quality test ---Care labeling ---Seam slippage test (for woven garments) ---Needle damage check (for knitted garment) ---GSM test ---Burn test (for 100% cotton garment) ---Seam strength (for sewn articles) ---Tensile properties ---Tearing strength, penetration resistance ---Thickness, compression, and recovery (for floor coverings) | |

Bags | |

QCIC technical engineers work closely with your team to design a specific bag or accessory inspection checklist. QCIC inspectors verify the quality of mass production based on your Acceptable Quality Limits (AQL), perform product function and safety tests, and assess compliance with your product's specifications and authorized samples. Your products' workmanship is carefully examined, and defects are classified into subcategories to highlight the key improvement areas for production. Main tests performed during an inspection of Bags ---Fitting test ---Using functions check ---Pull test on seam ---Color fastness test ---Smell test ---Metal detection test ---Stitches per inch check ---Inside stuffing check ---GSM check ---Loading test ---Abuse/fatigue test | |

Footwear | |

The Footwear industry produces hundreds of designs, each necessitating a slightly different manufacturing process. QCIC technical engineers work together with your team to incorporate your key risks and unique product specifications into our standard Footwear inspection checklist. QCIC inspectors verify the physical and mechanical properties of your products based on your Acceptable Quality Limits (AQL), perform product safety tests, and assess compliance with your product's specifications and approval samples. Main tests performed during an inspection of Footwear ---Sole bonding, seat piece, and sock liner adhesion ---Heel flexibility ---Symmetry check ---Heel attachment strength (high heels) ---Color shading ---Odor test ---Pull tests for components and accessories ---Size fitting test ---Weight test ---Colorfastness check (Rub test) ---Care labeling ---Waterproof test ---Fasteners fatigue and zip quality test ---Stitches per inch check ---Burn test (for 100% cotton garment) ---Adhesive check (logos, printings, markings fastness) | |

Toys | |

QCIC technical engineers work together with your team to customize our standard baby and children's toy inspection checklist to address your key risks and unique product specifications. QCIC's specialized inspectors monitor the whole manufacturing process, ensuring timely shipment of children's and babies toys that conform to destination specific safety regulations. We refer to toy standards from destinations such as the USA, EU, Australia, Canada, and Mexico including CPSIA, ASTM F963, EN71, IEC, ISO/TC 181, AS/NZS ISO 8124, SOR/2016-168, and NOM-252-SSA1-2011. Main tests performed during an inspection of Toys ---Sharp point and sharp edge verification ---Workmanship check ---Pull test on small parts ---Function/performance of product ---Pull test on seams ---Working distance check for remote control toys ---Stuff checking for the plush toy ---Frequency check for electronic toys ---Metal detection test ---Humidity test for the wooden toys ---Small parts verification |